OUR FOUNDER

Nelcast Limited was founded in 1982 by Mr P. Radhakrishna Reddy, a Metallurgical Engineer from Regional Engineering College, Nagpur. In the initial years, he handled all the key functions of Marketing, Production and Human Resources. Under his leadership, as the company went through its trailblazing journey of growth, he built a professional organisation that could further propel the company forward. Learn more about our founder with this video.

Mr P.Radhakrishna Reddy

(1955-2011)

Board of Directors

Nelcast has a distinguished group of Directors, each with a rich background, who deeply care about the Company, its employees and customers.

-

D. SESHA REDDY Chairman

D. SESHA REDDY Chairman -

P. DEEPAK Managing Director

P. DEEPAK Managing Director -

P. DIVYA Director

P. DIVYA Director -

R. SRIDHARAN Director

R. SRIDHARAN Director -

A. BALASUBRAMANIAN Director

A. BALASUBRAMANIAN Director -

MAHESWARI MOHAN Director

MAHESWARI MOHAN Director -

Vinod K Dasari Director

Vinod K Dasari Director

Our Strengths

Over the years, Nelcast has successfully focused on delivering value to customers by continually updating technology, improving skills, increasing productivity and augmenting infrastructure. These strengths have helped the Company gain a distinct edge over competition. While the Company has several achievements to its credit, there are a few specific advantages that put Nelcast at the winning line.

Diversified Customer Base

Over the years we have developed longstanding, extensive relationships with our customers and believe that we are amongst the preferred suppliers or partners to most top global and Indian customers. We have a diversified customer base including Original Equipment Manufacturers (“OEM”) and Tier-1 customers in the Commercial Vehicle, Tractor, Railways and Off-Highway Vehicle segments spread across India, Europe, North America and Southeast Asia. We are a trusted partner and a strategic supplier with long-standing strategic relationships with TAFE, Tata Motors, Ashok Leyland, Volvo-Eicher Commercial Vehicles, Same Deutz-Fahr India, Daimler, Automotive Axles, Dana, American Axles & Manufacturing, Comer Industries, Meritor, Wabtec, ZF.

Diversified product portfolio

Besides having a wide customer base across several industries and geographies, Nelcast also prides itself on being a one stop shop for our customers by being able to supply castings of several different grades and sizes:

- Material Grades produced:

- All standard grades of Grey & Ductile Iron as per

- Highly Pearlitic Grey Iron for Brake Disc Applications

- High Silicon-Molybdenum Ductile Iron for High Temperature Exhaust Manifolds

- All grades of Austempered Ductile Iron (In-house heat treatment facility)

Solution Strengthened Ferritic grades of Ductile Iron - Ductile Iron Castings with strong impact properties at Low Temperatures for Railway Braking & Windmill Applications

- Weight Range for Ductile Iron: 1.5 – 200 Kg

- Weight Range for Grey Iron: 35 – 250 Kg

- Ability to produce components from 50 parts/month to 30,000 parts/month

- Components can be supplied as Rough Castings or Fully Machined Sub-assemblies through in-house facilities and tie-ups with top machining vendors

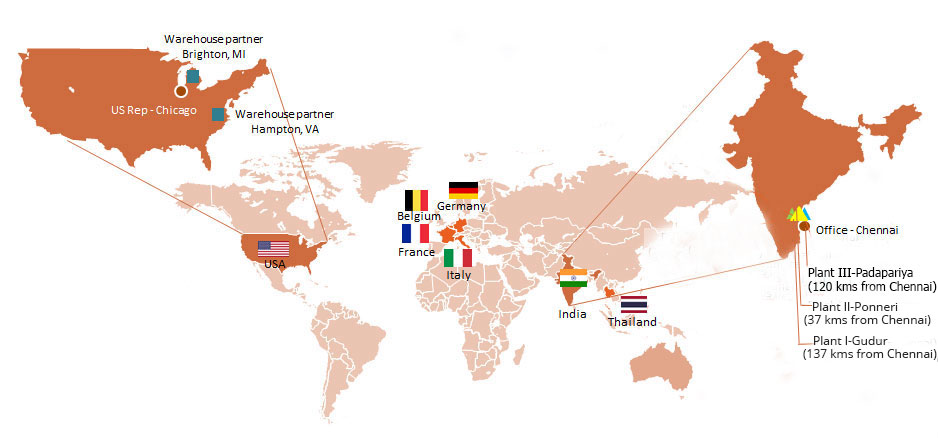

Strategic Locations

Nelcast’s plants are located in Gudur, Ponneri & Pedapariya which are located 140, 40 & 125 km respectively from the city of Chennai. Chennai is a major international airport which is well connected with direct flights to Europe, Middle-East & Southeast Asia. Chennai is also a major manufacturing hub with several leading global automotive companies which form both a key customer base and a reliable source of steel scrap which is a critical raw material. Gudur is also widely considered as the best source of silica sand for the foundry process. Our plants are also located close to both the Krishnapatnam & Chennai seaports which enable us to reach our customers in USA, Italy, Belgium, Sweden, France, Germany & Thailand easily.

State of Art Technology

- Equipped with Four High-Pressure Automated Moulding Lines

- Inhouse Research & Development facility accredited by DSIR, Government of India

- Well Physical & Chemical Labs with Standardized Quality procedures

- Computerized design and development using CAD/CAM/CAE tools

- Manufacturing of tooling through CNC Vertical Machining Centres

- Well equipped machining facility with CNC machines

Dedicated & Experienced Workforce

Nelcast has a vibrant workforce comprising highly qualified professionals and highly skilled and experienced workmen with an average experience of over 2 decades in the foundry industry. Proud of its track record, the organization has never had to suffer the loss of a single man hour due to labour unrest or other employee related causes. Clearly dedicated to both clients and employees, Nelcast offers its customers a reliable and stable ground to support their business.

milestones

| Year | achievements |

|---|---|

| 1982 | Incorporation of the Company |

| 1985 | Start of Commercial Production at Gudur Plant |

| 1990 | Entry into Tractor Segment |

| 1995 | Commencement of Exports to USA |

| 1996 | Start of Commercial Production at Ponneri Plant |

| 2001 | Commissioning of first High Pressure Automatic Moulding Line |

| 2004 | Commencement of Exports to Europe |

| 2007 | Listed on BSE and NSE |

| 2010 | ISO 14001 & ISO 18001 Accreditation awarded |

| 2013 | Commissioning of second High Pressure Automatic Moulding Line |

| 2014 | R&D Recognition by Dept. of Scientific & Industrial Research |

| 2016 | Commissioning of third High Pressure Automatic Moulding Line |

| 2016 | ISO 50001 Certification Awarded for Energy Management Systems |

| 2018 | IATF 16949 Certification Awarded |

| 2018 | Start of Commercial Production at Pedapariya Plant |

Presentations

Our Reach

Nelcast has three plants in India, and handle the manufacture and production of various casting components that the organization specializes in. The corporate office is located in Chennai, India.

Corporate office

159 TTK Road, Chennai – 600 018, India

Phone: +91-44-2498 3111 /+91-44-2498 4111

Fax: +91-44-2498 2111, E-mail: nelcast@nelcast.com

Plant I– Gudur

Specialization: Ductile Iron parts

Functions: Manufacture of castings and machining

Capacity: 60000T per annum

Address:

Nelcast Ltd,

34, Industrial Estate,

Gudur – 524101, Andhra Pradesh, India.

Phone: +91-8624-251266, 251766

Plant II– Ponneri

Specialization: Grey Iron and Ductile Iron parts

Functions: Manufacture of castings and machining

Capacity: 40000T per annum

Address:

Nelcast Ltd,

Madhavaram Village,Tiruvallur District,

PONNERI-601 204, Tamilnadu, India.

Phone: +91-44-27974165 / +91-44-27973552

Fax: +91-44-27973620

Plant III – Pedapariya

Specialization: Ductile Iron parts

Functions: Manufacture of castings and machining

Capacity: 18000T per annum

Address:

Nelcast Ltd,

259 & 261, Pedapariya Village, OZILI mandal,

Pedapariya-524402, Andhra Pradesh, India.

Phone: +91-8624-251266, 251766